Umatshini wokuWelding we-TIG 400TX4

| Inombolo yemodeli | YC-400TX4HGH | YC-400TX4HJE | ||

| Ilinganiswe igalelo lombane | V | 380 | 415 | |

| Inani lezigaba | - | 3 | ||

| Ilinganiswe igalelo lombane | V | 380±10% | 415±10% | |

| Ilinganiswe rhoqo | Hz | 50/60 | ||

| Igalelo elilinganisiweyo | TIG | kVA | 13.5 | 14.5 |

| Intonga | 17.85 | 21.4 | ||

| Isiphumo esilinganiselweyo | TIG | kw | 12.8 | 12.4 |

| Intonga | 17 | |||

| Amandla Factor | 0.95 | |||

| Ilinganiswe nge-No-Load Voltage | V | 73 | ||

| Imveliso yangokuuluhlu olunokulungiswa | T I G | A | 4-400 | |

| Intonga | A | 4-400 | ||

| Imveliso yombaneuluhlu olunokulungiswa | T I G | V | 10.2-26 | |

| Intonga | V | 20.2-36 | ||

| Ixesha lokuqala | A | 4-400 | ||

| I-Pulse yangoku | A | 4-400 | ||

| I-Crater yangoku | A | 4-400 | ||

| Ireyithwe uMjikelo woMsebenzi | % | 60 | ||

| Indlela yokulawula | Uhlobo lwe-IGBT Inverter | |||

| Indlela yokupholisa | Ukupholisa umoya ngenkani | |||

| Ijenereyitha ye-high-frequency | Uhlobo lwe-Spark-oscillation | |||

| Ixesha lokuhamba kwangaphambili | s | 0-30 | ||

| Ixesha lasemva kokuhamba | s | 0-30 | ||

| Ixesha lokuhamba phezulu | s | 0-20 | ||

| Ixesha le-Downslope | s | 0-20 | ||

| Ixesha lendawo yeArc | s | 0.1-30 | ||

| Ukuphindaphinda kwe-Pulse | Hz | 0.1-500 | ||

| Ububanzi be-Pulse | % | 5-95 | ||

| Inkqubo yolawulo lweCreyitha | Imowudi emithathu(VULA,VUMA,PHINDA) | |||

| Imilinganiselo (W×D×H) | mm | 340×558×603 | ||

| IMisa | kg | 44 | ||

| Iklasi ye-Insulation | - | 130℃ (ireactor 180℃) | ||

| Ukuhlelwa kwe-EMC | - | A | ||

| IP ikhowudi | - | IP23 | ||

Imele ulungelelwaniso olusemgangathweni

I-YT-158TP

(Ubukhulu bepleyiti esebenzayo: Ubuninzi. 3.0mm)

YT-308TPW

(Ubukhulu bepleyiti esebenzayo: Ubuninzi. 6.0mm)

YT-208T

(Ubukhulu bepleyiti esebenzayo: Ubuninzi. 4.5mm)

YT-30TSW

(Ubukhulu bepleyiti esebenzayo: Ubuninzi. 6.0mm)

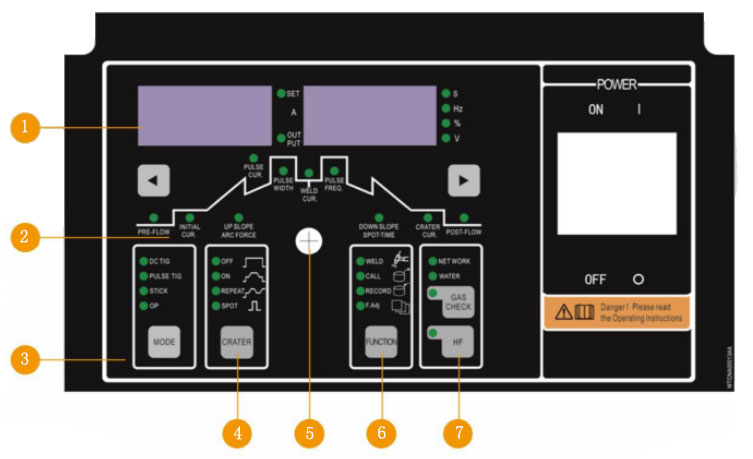

1. Iimitha zokuBonisa iiDijithali ezininzi eziSebenzayo

Amaxabiso angoku, amandla ombane, ixesha, Ukuphindaphinda, umjikelo womsebenzi, ikhowudi yempazamo inokuboniswa.Ubuncinane beyunithi elawulayo yi-0.1A

2. Imodi ye-TIG ye-Welding

1). Ukutshintsha imo ye-welding ye-TIG ngo-4, ukulungisa ulandelelwano lwexesha ngo-5 .

2). Ixesha lokuhamba kwerhasi kwangaphambili kunye nexesha lokuhamba kwexesha, amaxabiso angoku, i-pulse frequency, umjikelo womsebenzi kunye nexesha le-slop linokulungiswa xa kukhethwe iCrater On.

3). Uluhlu lohlengahlengiso lwe-pulse frequency yi-0.1-500Hz.

3. Iindlela ze-Welding ezintathu

1). DC TIG, DC PULSE & NINGA.

2). Xa i-Stick i-welding ikhethiwe, zombini i-acid & alkaline electrode iyasebenza kwaye i-arc-start & arc-force current ingalungiswa.

4. TIG welding mode switch

1). ukuwelda kunokumiswa ngokucinezela kabini iswitsha yetotshi xa [PHINDA] ikhethiwe.

2). ngaphandle kwexesha le-welding, i-slop inokulungiswa kwakhona xa [SPOT] ikhethiwe.

5. TIG welding mode switch

I-encoder yedijithali, jikelisa ukulungisa, cofa ukuqinisekisa

1). Ukuze kuqwalaselwe ukuthembeka kokusetyenziswa kwindawo enzima, isakhiwo sangaphakathi somatshini sithe tye.

2). I-loop yolawulo lwesekethe yeBhodi yePC inegumbi lokutywina elahlukileyo. Ibhodi yePC ifakwe ngokuthe nkqo ukuze kuthintelwe imfumba yothuli.

3). I-axial flow fan enkulu, i-air duct ezimeleyo, ukuchithwa kakuhle kobushushu

4). I-Multi-protection: i-primary overvoltage, i-undervoltage, ukhuseleko lwesigaba esivulekileyo; i-overcurrent yesibini, i-electrode short circuit, water- shjortage protection, ukhuseleko lokutshintsha ubushushu, njl.

6.Iisetingi zokusebenza

1. Iiparamitha zamaqela angama-100 zinokugcinwa kwaye zikhunjulwe.

2. [F.Adj] inokuseta/ilungise imisebenzi emininzi

Umsebenzi wokunciphisa wangoku: uluhlu luyi-50-400A

Umsebenzi wokuchasana nomothuko: lo msebenzi unokukhethwa xa udibanisa intonga kwindawo emanzi okanye emxinwa. Ukumiselwa komzi-mveliso KUVALIWE.

Umsebenzi wokulungisa i-Arc-start: i-arc-start yangoku kunye nexesha linokulungiswa.

Isiphaluka esifutshane sothusayo: siya kubetha xa i-electrode ye-tungsten kunye ne-workpiece imfutshane isiphaluka , iya kuthintela umonakalo we-tungsten electrode. ukutshisa (nceda bhekisa kwincwadana yokusebenza ngeseto ezongezelelweyo)

7.Arc-qalisa useto

I-high frequency arc-start and pull arc-start, isetyenziswa nakwiindawo apho i-frequency ephezulu inqatshelwe.