-

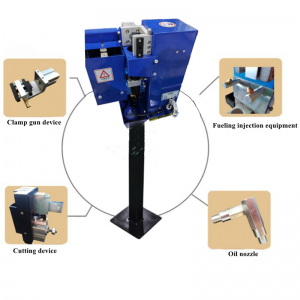

ISikhululo sokuCoca iTotshi yeWelding

Isixhobo sokucoca setotshi ye-welding

Uphawu JSR Igama isikhululo sokucoca itotshi yokuwelda Imodeli yesixhobo JS-2000s Umthamo womoya ofunekayo malunga ne-10L ngesekhondi Ulawulo lwenkqubo Umoya Umthombo womoya oxiniweyo Umoya owomileyo ongenawoli 6bar Ubunzima malunga ne-26kg (ngaphandle kwesiseko) 1. Ukucoca imipu kunye noyilo lokutshiza kwindawo enye yokucoca umpu kunye nendlela yokusika,irobhothi idinga kuphela-i-asignal ukugqiba ukucoca umpu kunye neentshukumo zokutofa amafutha. 2. Nceda uqinisekise ukuba amacandelo abalulekileyo ompu akhuselwe yi-aumgangatho ophezulu we-casing ukunqanda impembelelo yokungqubana, ukuchaphaza kunye nothuli. 1. Coca umpu Inokususa ngokufanelekileyo i-welding spatter encanyathiselwe kwi-nozzle ye-robot ye-welding eyahlukeneyo. Kwi-paste "ye-splash" enzima, ukucoca kwakhona kunemiphumo emihle. Isikhundla sombhobho we-welding ngexesha lenkqubo yokusebenza inikezelwa yibhloko ye-V yokubeka ngokuchanekileyo. 2. Tshiza Isixhobo sinokutshiza ulwelo oluchasene ne-spatter kwi-nozzle ukwenza ifilimu ekhuselayo, enciphisa ngokufanelekileyoukunamathela kwe-welding spatter kunye nokwandisa ixesha lokusebenzisa kunye nobomi bezixhobo. Indawo ecocekileyo ixhamla kwindawo yokutshiza etywiniweyo kunye nesixhobo esiseleyo sokuqokelela ioli 3. Ukucheba Isixhobo sokusika ucingo sibonelela ngomsebenzi ochanekileyo kunye nomgangatho ophezulu wokusika ucingo, sisusa intsalela yebhola etyhidiweyoekupheleni kwentambo yokuwelda, kwaye iqinisekisa ukuba i-welding inesiqalo esihle se-Arc. Ubomi benkonzo ende kunye neqondo eliphezulu lokuzenzekelayo.

www.sh-jsr.com

Iimveliso ezishushu - Imephu yesizaRobot Palletizer, IRobhothi yokuPeyinta ngokuzenzekela, Irobhothi yeWelding, Yaskawa Spot Welding Robot, I-Palletizing Robot, Yaskawa Painting Robot,

Fumana iphepha ledatha okanye isicatshulwa sasimahla

Bhala umyalezo wakho apha kwaye uwuthumele kuthi