1. Umatshini wokuwelda kunye nezixhobo

| Amacandelo | Imibandela efuna ingqalelo | Iziphumo |

| Welder | Musa ukulayisha ngaphezulu. Intambo yokuphuma ikhuselekile Iqhagamshelwe. | Ukutshisa i-welder. I-welding ayizinzanga kwaye i-joint iyatshiswa. |

| Itotshi yokuwelda | Iinxalenye ezitshintshayo kufuneka zitshintshwe ngexesha. Umkhono wokutyisa ucingo kufuneka ucocwe kwangethuba. | Ukutya ngocingo akuzinzanga kwaye akukwazi ukushiselwa ngokuqhelekileyo. Ukuxhathisa ukondla ucingo oluphezulu, alukwazi ukudityaniswa ngokuqhelekileyo. |

| Isixhobo sokutyisa ngocingo | Uhlengahlengiso loxinzelelo lwengalo luhambelana nobubanzi bocingo lwe-welding.

Umbhobho wocingo kufuneka ucocwe kwangethuba. | Ukuxhathisa ukondla ucingo oluphezulu, alukwazi ukudityaniswa ngokuqhelekileyo.

Ukuxhathisa ukondla ucingo oluphezulu, alukwazi ukudityaniswa ngokuqhelekileyo.

|

| Umkhono wokutyisa ucingo | Umbhobho wocingo kufuneka ucocwe kwangethuba.

Iradiyasi yokugoba akufunekanga ibencinci kakhulu. | Ukuxhathisa ukondla ucingo oluphezulu, alukwazi ukudityaniswa ngokuqhelekileyo. Ukuxhathisa ukondla ucingo oluphezulu, alukwazi ukudityaniswa ngokuqhelekileyo. |

| Ipleyiti yokutyisa ucingo | Nika ingqalelo kwi-disc shaft lubrication. | Ukuxhathisa ukondla ucingo oluphezulu, alukwazi ukudityaniswa ngokuqhelekileyo. |

2. Uhlalutyo lwamatyala athile obungozi kwisiza

Uninzi lweedrum zocingo zonakalise okanye azinasiciko, kwaye ucingo lutsalwa ngqo kumbhobho. Iziphumo ezimandundu zezi:(1) ucingo olukrweliweyo (2) ucingo olukrweliweyo alugudi (3) ucingo olukrweliweyo kwivili lokutya ngocingo kunye netyhubhu yocingo, ngenxa yokuba intambo yocingo ayigudi, isigqubuthelo socingo siyakuwa kwaye sivale isikhephe socingo. Ukukhokelela ekungazinzini kwe-welding, kodwa kwakhona kuchaphazela ubomi benkonzo yetyhubhu yocingo kunye nevili lokutyisa ucingo!

Ityhubhu yefidi yocingo yonakele kwaye isasebenza. Ucingo lwe-welding aluzange ludlule kwi-feeder yocingo ngokufanelekileyo. Kufuneka ngokuchanekileyo ngomatshini wokutyisa ucingo, lungisa uxinzelelo oluhambelanayo. Isizathu esibalulekileyo sesekethe emfutshane inokutshisa iintambo zangaphakathi zerobhothi!

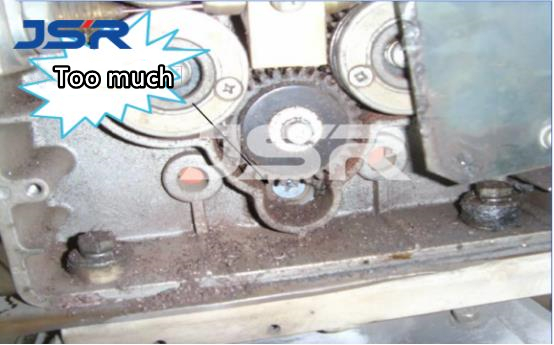

Isitshizi sewelding eninzi kunye nothuli!

Ikhebula likhululekile, lichaphazela umphumo we-welding. Iintambo ezintle kunye nezingalunganga zezinye ii-welders nazo zikhululekile.

Ukugcinwa + ukugcinwa = inzuzo

Ukugcinwa kobuchwephesha kwenkqubo yerobhothi ye-arc welding, nceda ufumane inkampani yokudibanisa inkqubo ye-welding, i-Shanghai Jiesheng Welding Technology Co., LTD., Ebandakanyeke kwi-welding system automation integration iminyaka engaphezu kwe-10, kunye nabasebenzi bezobugcisa kunye namava.

Ixesha lokuposa: Nov-09-2022