Kwinkqubo yokuvelisa imihla ngemihla, isitya soxinzelelo luhlobo lwenqanawa evaliweyo enokumelana noxinzelelo. Idlala indima ebalulekileyo kumacandelo amaninzi afana nezoshishino, ezoluntu kunye nezomkhosi, kunye nakwiinkalo ezininzi zophando lwezenzululwazi. Iinqanawa zoxinzelelo zisetyenziswa kakhulu kwishishini lemichiza kunye neshishini le-petrochemical, ngokukodwa ukuhanjiswa kobushushu, ukuhanjiswa kobuninzi, ukusabela kunye nezinye iinkqubo zobuchwepheshe, kunye nokugcinwa kunye nokuthuthwa kwegesi phantsi koxinzelelo okanye i-gas liquefied.

I-Welding yinkqubo ebalulekileyo yokuvelisa iinqanawa zoxinzelelo. Ngokomahluko wezinto eziphathekayo, ibakala, ukubunjwa kweekhemikhali kunye nokusebenza kwe-welding ye-welding, inkqubo ye-welding ibandakanya i-arc welding, i-arc welding ephantsi kwamanzi, i-tungsten argon arc welding, i-MIG welding kunye nokunye. Njengesakhiwo esiqhelekileyo se-welding, i-welding welds ebandakanyekayo kwi-welding ye-pressure welding ininzi i-curves yendawo enzima, kwaye kukho iimfuno eziphezulu zokudibanisa kwinkqubo yokuvelisa. Ukuphucula umgangatho we-welding kunye nenqanaba le-automation ye-automation kubaluleke kakhulu kwinqanawa yoxinzelelo kunye neshishini lonke lokuwelda.

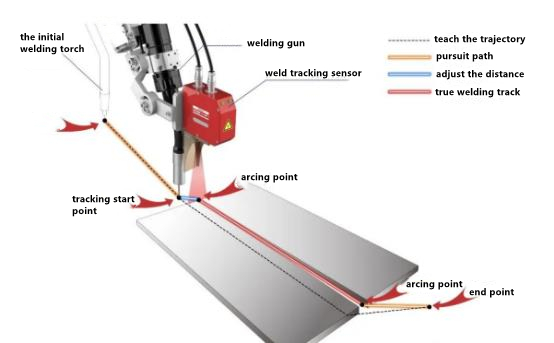

Ngophuhliso olukhawulezayo lwezixhobo ezizenzekelayo, itekhnoloji ye-welding ye-othomathikhi yenqanawa yoxinzelelo iya ikhula. iirobhothi Industrial baxhotyiswe nge laser welding inkqubo umthungo umthungo kunye nobude kunye lateral umkhondo oluzenzekelayo, kwaye emva koko baqonde umthungo welding oluzenzekelayo, kwaye iye yaba yindlela eqhelekileyo, unokusombulula ukuchaneka workpiece imathiriyeli engenayo, ukuchaneka tooling ngamanqanaba ezahlukeneyo impazamo. Ukunciphisa kakhulu umsebenzi wokufundisa iirobhothi ze-intanethi.

I-Shanghai JieSheng i-robot ezimeleyo edibeneyo ye-laser welding ebonakalayo ye-weld seam yokulandelela inkqubo, inokukhokela i-robot yokuqonda ixesha lokwenyani lokutshintsha kwe-weld okanye umatshini we-welding, ukulungiswa ngokuzenzekelayo komgca we-welding, iimveliso ezichanekileyo eziphezulu, ukugijima okuzinzileyo, isantya sokuphendula, ezisetyenziswa ngokubanzi kwizinto ezahlukeneyo ezifana ne-carbon steel, insimbi engenasici, i-aluminium alloy pressure isitya se-welding, i-TIG ekhulile, i-substrate ye-LAser ukuwelda kunye nezinye iinkqubo zemveliso.

Ixesha lokuposa: Nov-09-2022