Kutshanje, umhlobo womthengi we-JSR wenze ngokwezifiso iprojekthi yetanki yoxinzelelo lwerobhothi. Izinto zokusebenza zomthengi zineenkcazo ezahlukeneyo kwaye kukho iindawo ezininzi ekufuneka zidityaniswe. Xa uyila isisombululo esidibeneyo esizenzekelayo, kuyimfuneko ukuqinisekisa ukuba umthengi wenza i-welding elandelelanayo okanye i-spot welding kwaye usebenzisa ngokupheleleyo i-robot. Kuya kwenziwa. Ngeli xesha, ndafumanisa ukuba wayenamathandabuzo malunga nokukhetha isikhundla, ngoko i-JSR yazisa ngokufutshane kuwo wonke umntu.

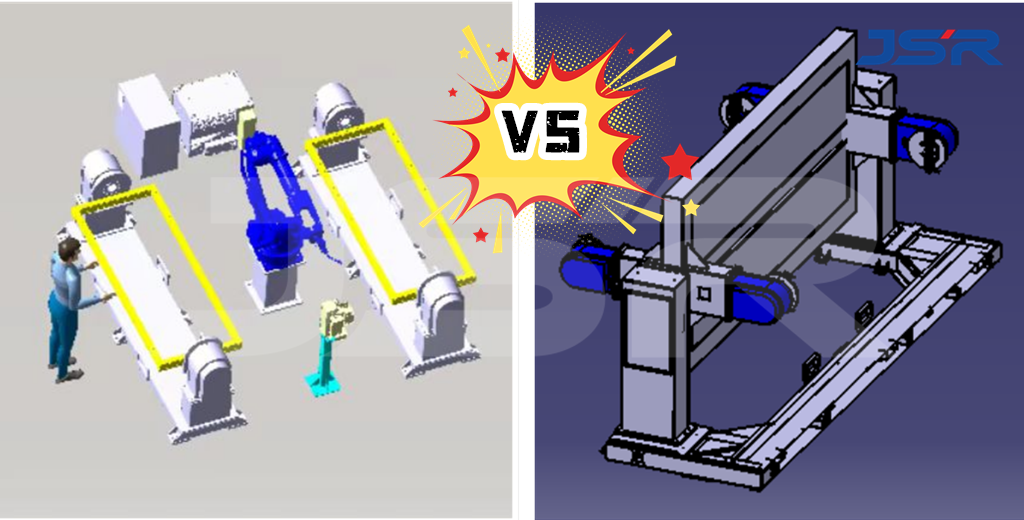

Izikhululo ezimbini ze-Single-axis Headstock kunye neTailstock Vertical Flip Positioner

I-VS i-Three-axis i-Vertical Flip Positioner

Kwindawo yokusebenzela yerobhothi yokuwelda, isikhululo sentloko-ezimbini-Single-axis kunye ne-tailstock nkqo kwi-flip positioner kunye ne-three-axis nkqo kwi-flip positioner zizixhobo ezibini zokumisa eziqhelekileyo, kwaye zineenzuzo zazo kwiimeko ezahlukeneyo zesicelo.

Ezi zilandelayo ziimeko zesicelo kunye nothelekiso:

Izikhululo ezimbini zentloko enye kunye nesakhelo sesakhelo somsila:

Ifanelekile kwiimeko apho i-workpiece kufuneka ijikelezwe kwaye ibekwe ngexesha lenkqubo ye-welding. Ngokomzekelo, kumgca wokuvelisa i-welding body welding, ii-workpieces ezimbini zingafakwa kwizikhululo ezibini ngaxeshanye, kwaye ukujikeleza kunye nokubekwa kwezinto zokusebenza kunokufezekiswa ngentloko ye-axis enye kunye ne-tailstock positioner, ngaloo ndlela kuphuculwe ukusebenza kakuhle kwemveliso.

https://youtube.com/shorts/JPn-iKsRvj0

Isibonisi-ndawo esimi nkqo se-axis ezintathu:

Ilungele iimeko ze-welding ezintsonkothileyo ezifuna ukujikeleza kunye nokuphephuka kwezixhobo zokusebenza kwiindlela ezininzi. Umzekelo, kwishishini le-aerospace, ukuwelda okuntsonkothileyo kweefuselage zenqwelomoya kuyafuneka. I-axis ezintathu ezithe nkqo kwi-flip positioner inokuqonda ukujikeleza kwe-multi-axis kunye nokujika kwendawo yokusebenza kumkhombandlela othe tye nothe nkqo ukuhlangabezana neemfuno zokuwelda kwii-engile ezahlukeneyo.

https://youtu.be/v065VoPALf8

Uthelekiso oluluncedo:

Izikhululo ezimbini zentloko enye kunye nesakhelo sesakhelo somsila:

- Isakhiwo esilula, kulula ukusebenza kunye nokugcina.

- Imisebenzi emibini inokucutshungulwa ngaxeshanye ukuphucula ukusebenza kakuhle kwemveliso.

- Ifanelekile eminye imisebenzi elula ye-welding, efana nezixhobo zokusebenza ezifuna i-axis enye yokujikeleza.

- Ixabiso lisezantsi kune-axis ezintathu ezithe nkqo kwiflip positioner.

- I-Welding itshintshelwa phakathi kwezikhululo zasekhohlo nasekunene. Xa bewelda kwisikhululo esinye, abasebenzi kufuneka balayishe kwaye bakhuphe izinto kwelinye icala.

Isibonisi-ndawo esimi nkqo se-axis ezintathu:

- Inokuqonda ukujikeleza kwe-multi-axis kunye ne-flipping kwaye ifanelekile kwimisebenzi ye-welding enzima.

- Ngexesha lokuwelda kwerobhothi, abasebenzi kufuneka bagqibezele ukulayisha kunye nokukhulula izixhobo zokusebenza kwicala elinye.

- Inika ukuguquguquka kokubeka ngakumbi kunye nokuchaneka, okunokuthi kuhlangabezane neemfuno zee-angles ezahlukeneyo ze-welding.

- Ilungele ii-workpieces ezinomgangatho ophezulu we-welding kunye neemfuno ezichanekileyo.

Ukushwankathela, ukukhetha indawo efanelekileyo kuxhomekeke kwiimfuno ezithile zomsebenzi welding, kubandakanywa izinto ezinjengobunzima be-workpiece, i-angle ye-welding, impumelelo yemveliso kunye neemfuno zomgangatho we-welding.

Ixesha lokuposa: Feb-20-2024